Precision and effectiveness are critical in the realm of production and machining. The choice of milling equipment plays a crucial role in achieving these goals, and one of the key decisions to make is whether to use 3-axis or 5-axis milling machines. Each has its own set of advantages and limitations, and understanding the differences between them is essential for making informed decisions in various industrial applications. In this comprehensive guide, we will delve into the world of milling, exploring what 3-axis and 5-axis milling entail, their respective capabilities, and the industries they serve.

Understanding 3-Axis Milling

- The Basics of 3-Axis Milling

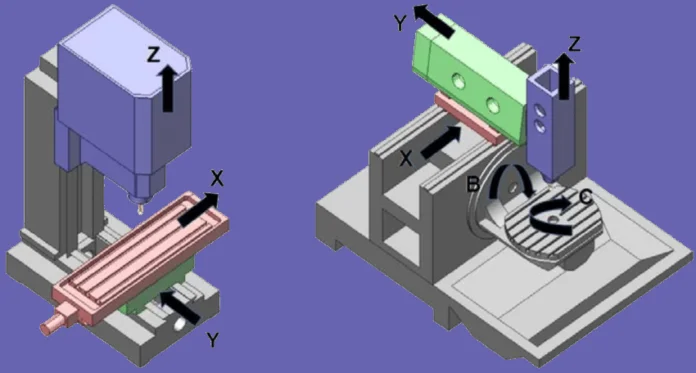

3-axis milling machines are among the most common and widely used tools in the machining industry. These machines operate in three primary directions: X, Y, and Z axes. The X-axis represents the horizontal movement, the Y-axis corresponds to the vertical movement, and the Z-axis signifies the depth or axial movement. In simpler terms, a 3 axis milling machine can move a workpiece along these three axes to create a wide range of shapes and features.

- Applications of 3-Axis Milling

3-axis milling machines are versatile and suitable for various applications, including:

- Prototyping: They are commonly used for rapid prototyping, allowing manufacturers to quickly create prototypes of new products.

- Production Machining: 3-axis machines are ideal for producing parts that do not require complex or intricate geometries.

- Mold Making: They are employed in making molds for injection molding and die-casting.

- Aerospace Components: Some aerospace components can be efficiently manufactured using 3-axis milling, especially those with simpler shapes.

- Limitations of 3-Axis Milling

While 3 axis milling machines are essential in many industries, they do have certain limitations:

- Complex Shapes: They struggle with producing complex parts that require multiple angles and curves.

- Undercuts: 3-axis machines cannot access areas underneath the workpiece, limiting their ability to create undercuts.

- Secondary Operations: For complex parts, secondary operations may be needed to complete the machining process.

Exploring 5-Axis Milling

- The Basics of 5-Axis Milling

5-axis milling takes machining to a whole new level by adding two rotational axes to the standard X, Y, and Z axes. These additional axes are typically referred to as A and B axes, allowing the cutting tool to move in multiple directions simultaneously. In essence, a 5-axis milling machine can manipulate the workpiece with unparalleled precision and versatility, enabling the creation of highly complex and intricate components.

- Applications of 5-Axis Milling

The capabilities of 5-axis milling machines open doors to a wide range of applications, including:

- Aerospace Industry: Creating complex aerospace components with tight tolerances is a common use case.

- Medical Devices: The intricate geometries required for medical implants and devices are achievable with 5-axis milling.

- Automotive Manufacturing: Prototyping and producing car parts, especially those with complex contours, benefit from 5-axis capabilities.

- Tool and Die Making: Crafting precision tools and die that demand intricate details and shapes.

- Advantages of 5-Axis Milling

The advantages of 5-axis milling are numerous:

- Complex Geometry: It can easily create complex shapes and features, reducing the need for secondary operations.

- Reduced Setup Time: 5-axis machines can often complete a part in a single setup, reducing downtime and improving efficiency.

- Improved Surface Finish: The simultaneous movement in multiple axes leads to smoother surface finishes.

- Tight Tolerances: Achieving tight tolerances is more feasible with 5-axis machining.

- Limitations of 5-Axis Milling

Despite its versatility, 5-axis milling also has some limitations:

- Cost: 5-axis machines tend to be more expensive to purchase and maintain than 3-axis machines.

- Complexity: Operating and programming 5-axis machines can be more complex and time-consuming.

- Operator Skill: Skilled operators are required to maximize the potential of 5-axis milling.

Conclusion

In the world of manufacturing and machining, the choice between 3-axis and 5-axis milling is a crucial one that can significantly impact the efficiency, precision, and cost-effectiveness of the production process. While 3 axis milling machines are versatile and suitable for a wide range of applications, 5-axis milling machines offer unparalleled capabilities for creating complex and highly precise parts. When making the decision between the two, it’s essential to consider the specific requirements of your industry and the complexity of the components you need to produce. While 5-axis milling machines come with a higher initial investment and require skilled operators, they are indispensable for industries where intricate geometries, tight tolerances, and superior surface finishes are paramount. On the other hand, 3-axis milling machines remain a cost-effective choice for simpler parts and applications where complexity is not a primary concern.