Introduction

As pet ownership continues to rise worldwide, so does the demand for high-quality and nutritious pet food. In response to this growing trend, the pet food industry is experiencing a wave of innovation that is transforming the way pet food is produced. Advancements in technology and a greater emphasis on sustainability have paved the way for cutting-edge pet food machines that cater to the specific needs of our furry companions. In this blog, we will explore the latest innovations in pet food machines, highlighting their benefits and how they are revolutionizing the pet food production process.

1. Automated Ingredient Mixing Systems

Traditional pet food production methods often involved manual handling of ingredients, leading to inconsistencies and inefficiencies. However, with the advent of automated ingredient mixing systems, manufacturers can now ensure a consistent blend of ingredients, resulting in a well-balanced and nutritionally-rich pet food formula. These advanced machines can precisely measure and mix the ingredients, taking into account the specific dietary requirements of different pet breeds, ages, and health conditions.

Types of Pet Food Mixing Machines

Pet food mixing machines come in various types, designed for different purposes and production scales.

- Ribbon Blender: A common type, that uses a ribbon-like agitator to blend dry and wet ingredients uniformly.

- Paddle Mixer: Utilizes paddles to mix ingredients; suitable for both dry and wet pet foods.

- Vertical Cutter Mixer: Chops and mixes ingredients vertically; ideal for small-scale operations.

- Horizontal Mixer: Mixes ingredients horizontally, suitable for larger-scale pet food production.

- Double Cone Blender: Conical shape allows thorough mixing of ingredients for dry pet foods.

- Planetary Mixer: Features rotating blades that cover the entire mixing container, ensuring even blending.

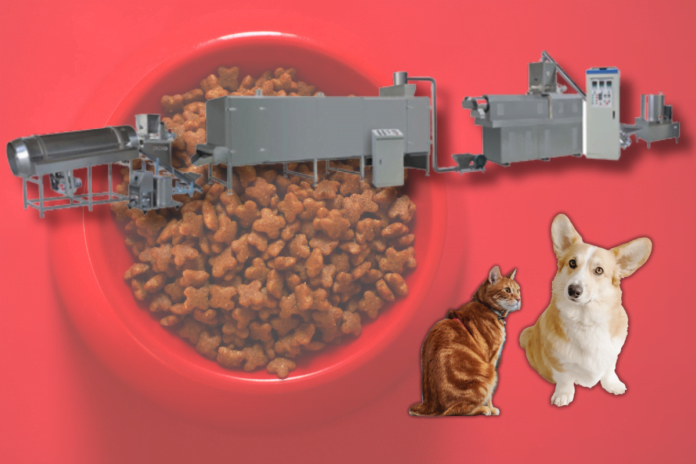

2. Extruders for Enhanced Nutrient Retention

Extrusion equipment in pet food production has been a game-changer. Stainless Steel Pet Food Extruders are machines that use heat and pressure to process pet food ingredients into different shapes and forms. This process not only improves the taste and texture of the final product but also enhances nutrient retention. The ability to retain more nutrients ensures that pets receive the essential vitamins, minerals, and proteins they need for optimal health.

3. 3D Printing for Customized Pet Food

One of the most exciting innovations in pet food machines is the integration of 3D printing technology. 3D printers can create customized pet food based on an individual pet’s nutritional needs, age, weight, and health conditions. This level of personalization ensures that pets get the precise nutrients required to maintain their well-being. Moreover, 3D printing also reduces food waste since it produces the exact amount needed for each pet, minimizing excess inventory.

4. Sustainable Packaging Solutions

As the world becomes more conscious of environmental issues, the pet food industry is also striving to reduce its ecological footprint. Innovative pet food machines now include sustainable packaging solutions that use biodegradable materials, recyclable packaging, and eco-friendly printing techniques. By adopting sustainable packaging practices, pet food manufacturers are not only appealing to environmentally conscious consumers but also contributing to a cleaner, greener planet.

5. IoT-Enabled Smart Feeders

Pet owners are increasingly looking for ways to monitor and manage their pets’ diets more effectively. IoT (Internet of Things)-enabled smart feeders offer a solution to this demand. These intelligent feeders can be programmed remotely through smartphone apps, allowing pet owners to control portion sizes, and feeding times, and even monitor their pet’s eating habits in real-time. Some smart feeders also incorporate AI algorithms to detect changes in a pet’s eating patterns, which can indicate potential health issues.

Conclusion

The pet food industry is undergoing a profound transformation, driven by innovative pet food machine manufacturers in Dubai and other countries that prioritize nutrition, sustainability, and personalization. These advancements are not only benefiting pets by providing them with healthier and more tailored diets but also supporting pet owners in managing their pets’ nutrition with greater ease and accuracy. As technology continues to evolve, we can expect even more remarkable developments in pet food production, further strengthening the bond between humans and their beloved animal companions. With a commitment to research, sustainable practices, and the well-being of our furry friends, the future of pet food production looks brighter than ever before.